Product Description:

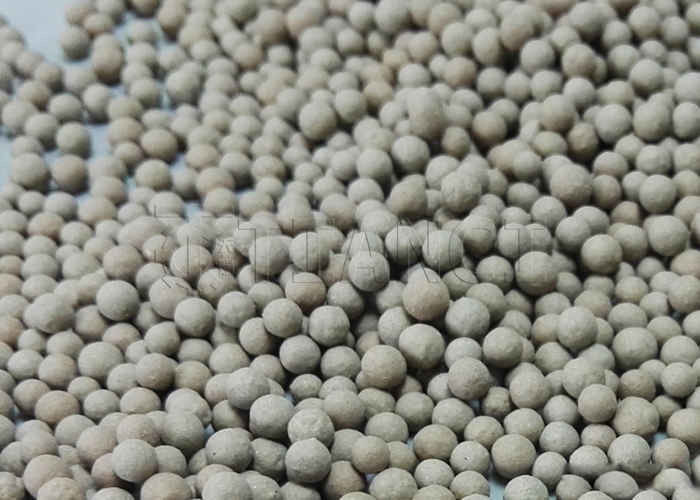

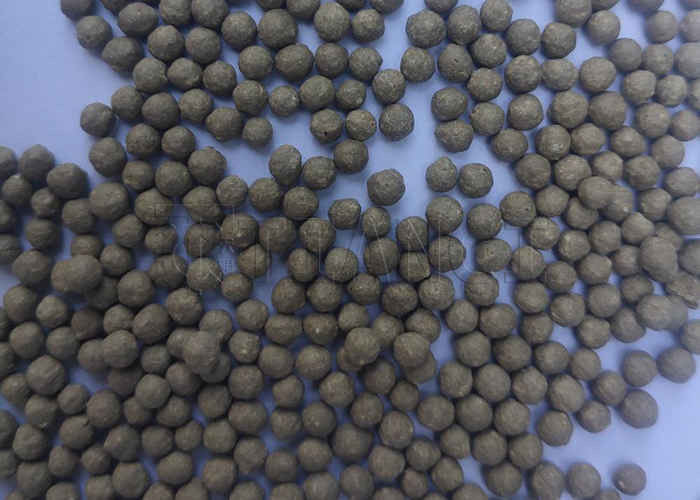

The Bentonite Cat Litter Granulator is a professional machine designed for producing high-quality cat litter pellets from bentonite powder, corn starch, cassava starch, and other fine materials. It adopts an advanced disc granulation system, which ensures uniform particle size, smooth surface, and strong granules that resist breaking during packaging and transport.

This cat litter granulation machine operates with low energy consumption and stable performance. The granulation disc angle and rotation speed can be precisely adjusted to control pellet size according to production needs. Its structure is simple but durable, featuring thick steel plates and an anti-corrosion coating to ensure long service life, even in continuous production environments.

The bentonite granulating equipment is widely used in pet litter manufacturing plants, chemical material processing, and powder pelletizing industries. It can be easily integrated into a complete cat litter production line, including feeding, mixing, granulating, drying, and screening systems.

With high forming rate, low dust emission, and easy maintenance, this machine helps manufacturers improve productivity, reduce waste, and achieve a clean, eco-friendly production process. It is an ideal choice for companies looking for reliable performance and consistent pellet quality in large-scale or medium-scale cat litter production.

Features:

- Suitable for bentonite, corn starch, cassava starch, and similar fine powders

- Adjustable disc angle and speed for precise granule control

- Strong, uniform cat litter pellets with high forming rate

- Durable, corrosion-resistant structure for long-term operation

- Energy-efficient and easy to maintain

- Ideal for pet litter, chemical, and environmental protection industries

Technical Parameters:

| Main Parameter |

| Model |

Disc Diameter (mm) |

Disc Height (mm) |

Disc Thickness (mm) |

Volume (m³) |

Rotary Speed (r/min) |

Power (kw) |

Capacity (t/h) |

Tilt Angle (°) |

| ZL10 |

1000 |

250 |

5 |

0.4 |

24 |

2.2 |

0.3-0.5 |

35°-65° |

| ZL15 |

1500 |

300 |

5 |

1.1 |

22 |

5.5 |

0.5-0.8 |

35°-65° |

| ZL18 |

1800 |

300 |

5 |

1.4 |

18 |

5.5 |

0.6-1.0 |

35°-65° |

| ZL20 |

2000 |

350 |

5 |

1.8 |

18 |

7.5 |

0.8-1.2 |

35°-65° |

| ZL25 |

2500 |

350 |

5 |

2.5 |

18 |

7.5 |

1.0-1.5 |

35°-65° |

| ZL28 |

2800 |

400 |

5 |

3.3 |

18 |

11 |

1.0-2.5 |

35°-65° |

| ZL30 |

3000 |

450 |

5 |

3.9 |

16 |

11 |

2.0-3.0 |

35°-65° |

| ZL32 |

3200 |

500 |

5 |

4.3 |

13.6 |

15 |

2.0-3.5 |

35°-65° |

| ZL36 |

3600 |

550 |

8 |

5.5 |

11.3 |

22 |

3.0-5.0 |

35°-65° |

| ZL45 |

4500 |

600 |

8 |

6.5 |

8 |

30 |

4.0-6.0 |

35°-65° |

Applications:

The Bentonite Cat Litter Granulator is widely used in various industries that require high-quality pellet production from fine powders. Its main applications include:

1.Pet Litter Manufacturing:

- Produces uniform and durable bentonite cat litter pellets with excellent absorbency and odor control.

- Suitable for small, medium, and large-scale cat litter production lines.

2.Powder Granulation Industry:

- Ideal for corn starch, cassava starch, and other food-grade powders.

- Converts fine powders into round, consistent granules for easy handling and packaging.

3.Chemical and Mineral Processing:

- Can granulate bentonite, clay, and other mineral powders for industrial or commercial use.

- Ensures stable pellet size and quality for further processing or transport.

4.Environmental and Eco-friendly Applications:

- Suitable for eco-friendly absorbent pellets used in animal husbandry, waste treatment, and water purification.

5.Integration into Complete Production Lines:

- Can be combined with mixers, dryers, sieving machines, and packaging systems to create a full bentonite cat litter production line.

- Ensures efficient, low-dust, and cost-effective production for manufacturers.

Support and Services:

At Tianci Heavy Industry Machinery, we are committed to providing complete support and services to ensure every customer achieves the best results from our equipment. From project planning to after-sales maintenance, our team offers professional assistance at every stage.

1. Pre-sales Consultation

We help customers choose the most suitable machines according to their materials, capacity, and production needs. Customized design and technical solutions are available to meet specific project requirements.

2. Installation and Training

Our experienced engineers can guide installation on-site or online. We also provide detailed operation manuals and training to ensure smooth and efficient production startup.

3. After-sales Service

We offer long-term technical support, quick spare parts supply, and regular maintenance guidance. Any issues are addressed promptly to minimize downtime and keep your production running steadily.

4. Global Support

With successful projects in over 200 countries, we understand the needs of different markets and provide reliable service wherever you are.

At Tianci, our mission is not only to deliver high-quality machines but also to build lasting partnerships through trust, professionalism, and continuous support.

FAQ:

Q1: What materials can the disc granulator process?

A1: The disc granulator is suitable for a wide range of powder materials, including bentonite cat litter, organic fertilizer, compound fertilizer, ceramic powder, and chemical materials. It can shape fine powders into round, uniform pellets efficiently.

Q2: What is the capacity range of the disc granulator?

A2: We offer various models with capacities from 1 to 10 tons per hour. Custom designs are available according to your production scale and material characteristics.

Q3: How does the disc granulator work?

A3: The machine uses a rotating inclined disc to roll and agglomerate materials into spherical granules. With the help of controlled moisture or binder, the powders gradually form uniform pellets during rotation.

Q4: What are the advantages of using a disc granulator?

A4: It features a high granulation rate (up to 90%), low energy consumption, stable operation, and easy maintenance. The pellet size can be adjusted by changing the disc angle or material moisture.

Q5: Do you provide installation and after-sales service?

A5: Yes. We offer on-site or online installation guidance, operator training, and long-term technical support. Spare parts are available quickly to ensure continuous production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!