Description:

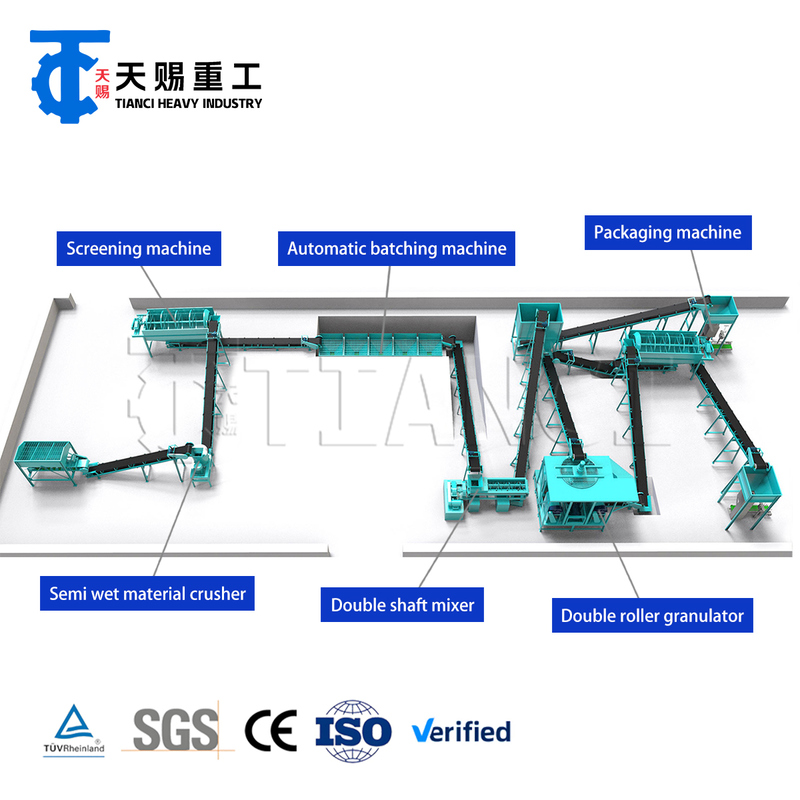

The double roller granulator compound fertilizer line offers an efficient and cost-effective solution for producing dense, high-strength NPK granules. Its dry extrusion process eliminates the need for drying or heating, reducing energy use and simplifying installation. The compact design fits various plant capacities.

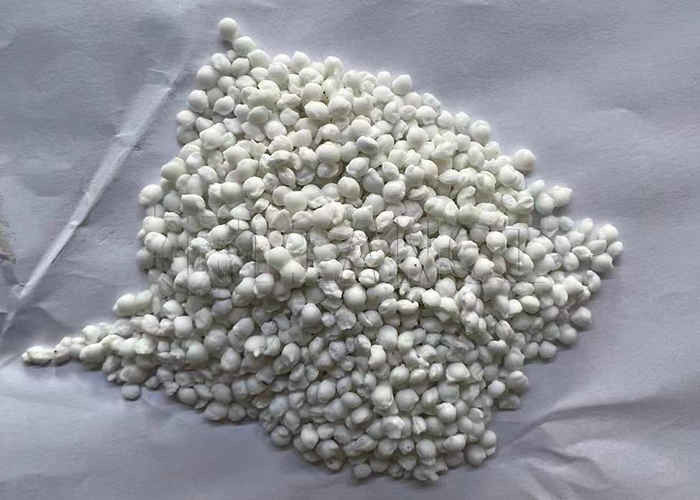

It handles a variety of raw materials, including urea, MAP, DAP, potassium sulfate, and other fine chemical powders. The resulting granules are uniform, moisture-resistant, and easy to store and transport.

Ideal for agricultural applications, this line enhances nutrient efficiency, boosts crop yields, and supports sustainable farming practices, making it perfect for modern fertilizer production.

Features:

1.High-Quality Granules – Produces dense, uniform granules with strong integrity.

2.Dry Extrusion – Converts powdery fertilizers into granules without water or drying.

3.Adjustable Size – Granule diameter can be easily modified for different needs.

4.Energy-Saving & Low Maintenance – Efficient design reduces energy use and upkeep.

5.Wide Material Compatibility – Suitable for NPK, ammonium phosphate, potassium chloride, and other powders.

6.Durable Build – Wear-resistant construction ensures long-lasting, stable operation.

Technical Parameters:

| Technical Parameter |

Details |

| Granulation Method |

Dry Extrusion Granulation |

| Keywords |

Compound Fertilizer Production Equipment |

| Granules Shape |

Elliptical, Flat-spherical, Block-shaped, Or Irregular Flaky Granules |

| Power |

50-360KW |

| Port |

Qingdao, Tianjin, Shanghai |

| Production Capacity |

1-10T/H |

| Color |

Customized |

| Installation |

On-site Installation |

| Processing Technology |

Feeding, Crushing, Mixing, Granulating, Drying, Cooling, Screening, Packaging |

| Granule Size |

2-8mm |

Applications:

1.Versatile Fertilizer Production – Produces NPK, NP, NK, and other multi-nutrient fertilizers.

2.Dry Powder Granulation – Turns fine chemical powders into dense, durable granules.

3.Agricultural Efficiency – Ensures uniform granules and stable nutrients for large-scale farming.

4.Customizable Blends – Supports specialty formulations to meet specific crop and soil needs.

Finished Granules Display:

Customization:

Our production lines are highly flexible and can be tailored to meet your specific needs. We offer customization options such as logo printing, machine color, motor type, material selection, capacity, and power configuration. This ensures that every production line is optimized for your requirements and branding.

Support and Services:

We are committed to providing our customers with comprehensive support and reliable services. Our company offers free process design drawings tailored to your needs, as well as free trial testing services to ensure optimal machine performance. Every machine comes with a one-year warranty for worry-free operation. In addition, we provide free installation and professional training services, helping your team quickly master the equipment and achieve efficient production.

FAQ:

Q1: What types of finished products can this fertilizer production line produce?

A1: Our production line can produce various types of granules such as organic fertilizer, compound fertilizer, andblended fertilizer. The production capacity, granule shape, and size can be customized according to customerrequirements.

Q2: What raw materials is the production line suitable for?

A2: It can process a variety of organic and inorganic materials such as animal manure, compost, agricultural waste,chemical powders, and phosphate rock powder.

Q3: I know little about the fertilizer production line. How to choose the most suitable machine?

A3: Just tell us your raw materials, capacity (tons/hour), and the size of the final granule product, and we willrecommend the suitable machine for you based on your specific situation.

Q4: How can I know my raw material is suitable for your machine?

A4: If we can buy the same raw material from our market, we wil test the machine, then send the video and show thefinal effection. If we can't buy it from our market, you can send it to our company, then we will arrange to testmachine for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!