Product Introduction

This NPK Fertilizer Production Plant delivers a all-in-one solution for crafting balanced fertilizers—blending the long-term soil-nourishing benefits of organic matter with the fast-acting, essential inorganic nutrients (nitrogen, phosphorus, potassium). Our fully customizable systems enable you to produce high-performance fertilizers tailored to specific crop requirements and soil conditions, supporting sustainable agriculture while reducing overreliance on purely synthetic inputs.

Parameter

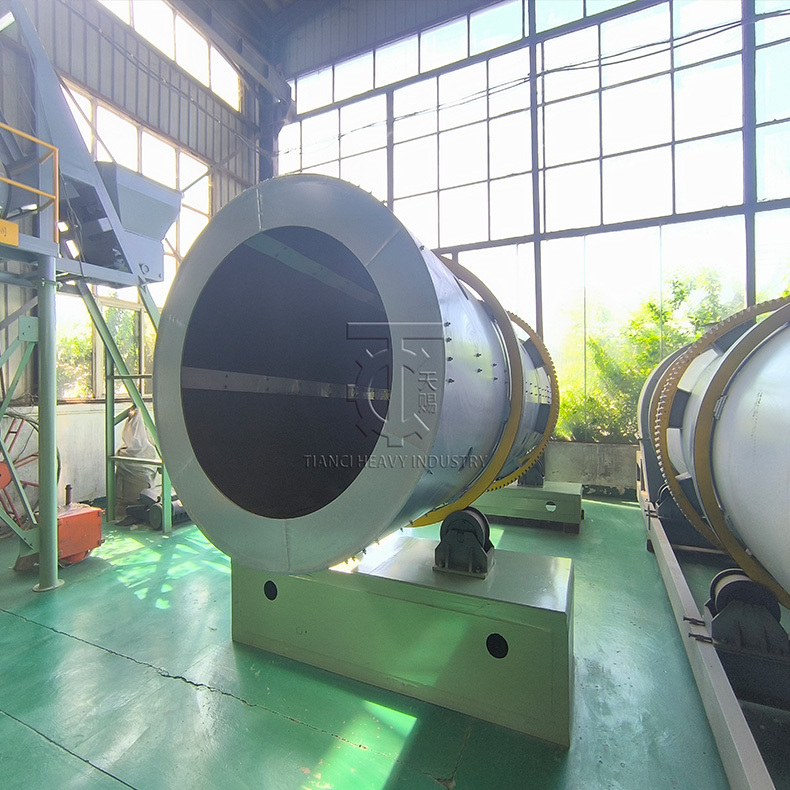

|

Model

|

Inner diameter

(m)

|

Inclination

(° )

|

Rotation speed

( r/min )

|

Power

( kw)

|

Capacity

( t/h )

|

|

ZG1240

|

1.2

|

2-5

|

4.7

|

5.5

|

1-3

|

|

ZG1450

|

1.4

|

2-5

|

5

|

7.5

|

3-4

|

|

ZG1560

|

1.5

|

2-5

|

5

|

11

|

5-8

|

|

ZG1870

|

1.8

|

2-5

|

3.9

|

15

|

8-10

|

|

ZG2080

|

2

|

2-5

|

3.9

|

18.5

|

10-15

|

|

ZG2290

|

2.2

|

2-5

|

3.2

|

22

|

15-20

|

|

ZG24100

|

2.4

|

2-5

|

3

|

30

|

20-25

|

Working Process

1.Raw Material Preparation: NPK,Organic materials (e.g., manure, crop residues) undergo fermentation (to decompose and sterilize) and crushing; inorganic materials are crushed and pre-processed to ensure uniform particle size for mixing.

2.Automated Batching & Mixing: The system automatically meters and blends prepped organic and inorganic materials according to the target fertilizer formula, ensuring homogeneous mixing.

3.Granulation: The mixed material is fed into a granulator (rotary drum, disc, or extruder) to form spherical or cylindrical granules of the desired size.

4.Drying: Granules are dried at a low temperature (approximately 90°C)—preserving heat-sensitive organic components and beneficial microbes while reducing moisture to 10-15%.

5.Cooling: Dried granules are cooled to ambient temperature via a cooling system, stabilizing their structure and preventing moisture reabsorption.

6.Screening: Granules pass through a vibrating screen to separate oversized/undersized particles (which are recycled back to the mixing stage) and retain uniformly sized products.

7.Optional Coating: Uniform granules are coated (if required) with functional materials to enhance nutrient release control or anti-caking properties.

8.Packaging: Finished granules are automatically weighed, filled into bags (25kg, 50kg, or bulk), and sealed for storage or shipment.

Q&A

Q: Does your factory offer after-sales service for the equipment sold?

A: Yes. We provide after-sales service coverage for all equipment purchased from our factory.

Q: How much NPK fertilizer can a drum granulator produce in one year?

A: The TIANCI drum granulator can produce 10,000 to 600,000 tons of NPK compound fertilizer annually. To meet customers' demands for higher output, we offer customization services.

Q: Could you please confirm whether installation services for the drum granulator are available following its purchase?

A: Yes. After the equipment arrives at your factory, we will send experienced engineers to your site to provide installation guidance and ensure the equipment operates normally.

Q: Could you please specify the hourly output range of your drum granulator?

A: The standard hourly output of our drum granulator ranges from 1 to 25 tons. If you have higher output demands (e.g., over 25 tons per hour), we can tailor a customized solution based on your specific production needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!