Organic compound fertilizer flat die extrusion granulator mineral feed granulator

Product Description:

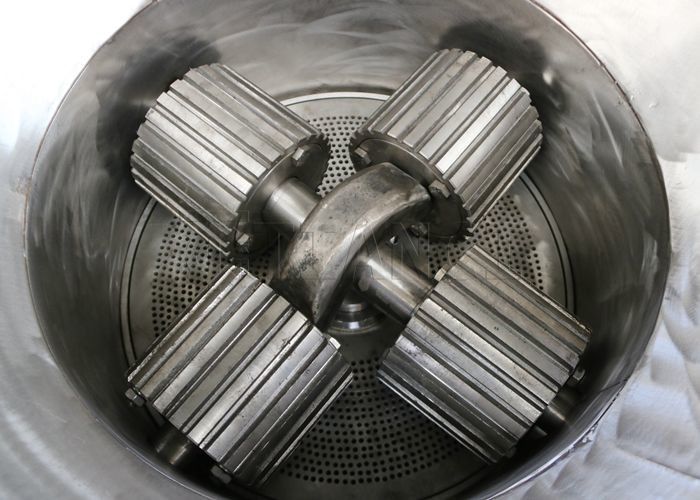

The functioning principle of this machine is a kind of granulation molding method between dry and wet granulation, so it is also called semi-dry granulation. The material added to the machine is laid flat on the top of the open flat mold, and the main shaft drives the grinding roller to rotate around the main shaft, and at the same time, the grinding roller rotates around the roller shaft. Grinding rollers continue to lay on the open template of the material layer pressure, the material in the template and grinding rollers formed by the Deed-shaped area is forced from the template holes in the extrusion. The extruded cylindrical strip is cut off (or naturally broken) by a scraper under the template, thus obtaining cylindrical particles. The diameter of the granules is generally 2-12mm, with a high granulation rate. In the pelletizing process, the wet content required for material pelletizing is lower than that required for screw extrusion pelletizing, and the pellet strength is higher than that of screw type extrusion pelletizing.

Features:

1.High granulation rate, no need to sieve, no return material.

2.Low moisture requirement for granulation, higher strength of molded particles, low secondary pulverization rate.

3.Due to the low moisture requirement of granulation, the energy consumption of the subsequent drying process is also relatively low. For some materials, the granulation process without drying can also be realized.

4.The capacity of single machine can reach 1.5-5kg/h.

Parameter

| Model |

KP-400 |

KP-600 |

KP-800 |

| Output (t/h) |

1.8-2.5 |

2.5-3.5 |

4-5 |

| Granulation rate |

>95 |

>95 |

>95 |

| Granule temperature |

<30 |

<30 |

<30 |

| Granule diameter(mm) |

3-30 |

3-30 |

3-30 |

| Power (kw) |

22 |

45 |

75 |

| Weight (kg) |

1200 |

1800 |

2500 |

Applications:

Typical application materials: activated carbon, carbon powder, coal powder, plant fiber, fermentation waste, compound fertilizers, bio-fertilizers, additives, catalysts, pesticides, potter's clay, lead oxide, zinc oxide and so on.

Support and Services:

Our Fertilizer Granulator Product Technical Support and Services are dedicated to ensuring that your experience with our product is efficient. We provide a comprehensive suite of services to assist with any technical challenges you may encounter during the operation of your Fertilizer Granulator. Our services include:

Technical Assistance: Our team of skilled technicians is available to provide guidance and answer any questions related to the features, setup, and use of the Fertilizer Granulator. They can help troubleshoot issues and offer solutions to get your equipment up and running smoothly.

Operational Training: To help you get the most out of your investment, we offer operational training sessions. These sessions are designed to familiarize your staff with the granulator's functions, maintenance procedures, and safety protocols.

Parts and Repair Services: In the event that your machine requires repair or replacement parts, we provide timely assistance. We supply authentic, high-quality parts to ensure your granulator operates at its best. Our repair services are carried out by certified professionals who specialize in our Fertilizer Granulator systems.

We are committed to delivering exceptional technical support and services to ensure that your Fertilizer Granulator operates at peak performance. Our goal is to help you achieve optimal results and maximize the productivity of your agricultural operations.

Packing and Shipping:

Wooden package or full 20GP/40HQ container;

The Fertilizer Granulator is packaged in sturdy wooden crates to provide maximum protection during transportation. Each crate is designed to fit the specific dimensions of the granulator and is lined with shock-absorbing materials to prevent any damages during handling and shipping.

The crates are also sealed tightly to prevent any dust or moisture from entering and potentially affecting the quality of the product. We take extra care to package the granulator in a way that it can withstand rough handling and long-distance transportation.

We ship our Fertilizer Granulator through reliable and trusted shipping companies to ensure timely and safe delivery. Our team works closely with these companies to track and monitor the shipment to make sure it reaches its destination without any delays or damages.

FAQ:

Q: Do you have customer reviews or case studies available ?

A: Yes, we have many successful overseas cases and customers feedback, such as Uzbekistan, Malaysia, Vietnam, India, Philippines and so on. If you need, you can add my whatsapp number and I will send them to you.

Q: What is your main products?

A: Our main products include complete equipments of fertilizer production line. There are many types of granulator and some auxiliary equipment (drying&cooling machine, screening machine, coating machine, packaging machine and so on).

Q: How to choose the right fertilizer equipment ?

A: Inder to choose the appropriate equipment, we need to know your fertilizer raw materials and production capacity, so that we can give you a right solution. It’s best for us if you can provide the production area.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!