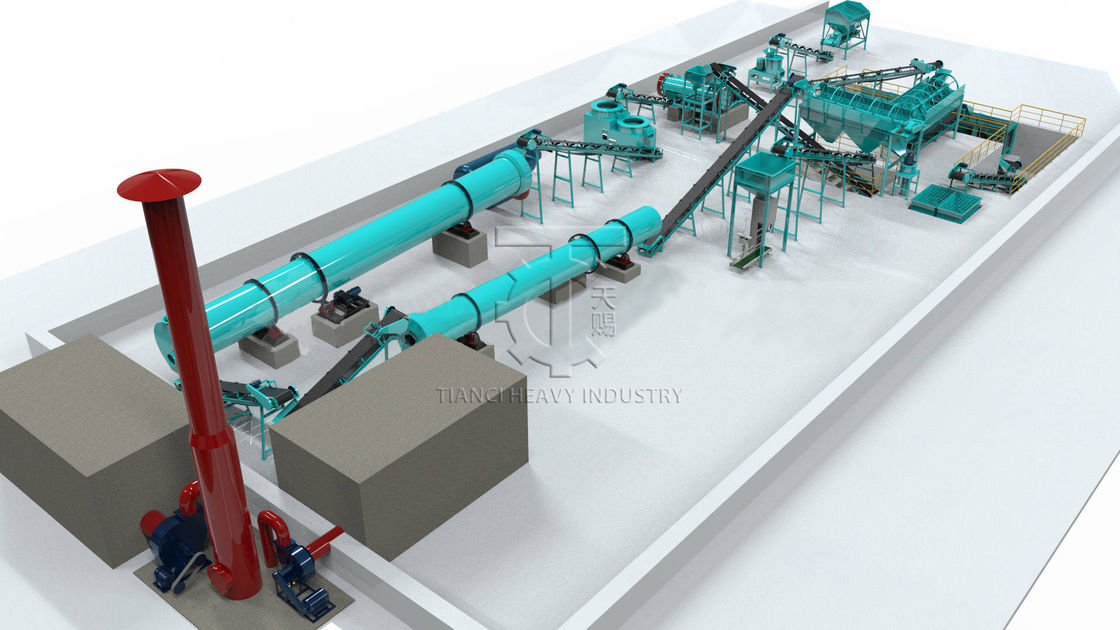

Organic Chicken Manure Fertilizer Granule Making Machine Fertilizer Production Line

The organic fertilizer production line processes fertilizers into granular form. Organic fertilizers primarily originate from plant and animal sources. Their primary purpose is to enrich soil and provide essential nutrients for plants. The production line effectively removes harmful substances while retaining beneficial nutrients. This project promotes the resource utilization of agricultural waste by converting livestock manure, crop stalks, and other waste into organic fertilizer. It reduces waste discharge and treatment needs, thereby aiding environmental protection.

Features:

- Waste utilization: turning livestock farm waste into treasure.

- The production line of granules organic fertilizer is a complete fertilizer production process with more investment.

- Fertilizer granulation has improved agricultural technology. Fertilizer granules can slowly release the fertilizer effect, are easy to apply, and are not easily blown away by the wind.

- The finished fertilizer processed by the pellet organic fertilizer production line can be preserved for a long time.

Main equipment of organic fertilizer production line:

|

① Fermentation machine

|

Mainly used for the fermentation of raw materials, to achieve industrial production, no dead ends.

|

|

② Crushing machine

|

Mainly used for the crushing of raw materials to meet the requirements of granulation

|

|

③ Mixing machine

|

It is used for mixing and stirring materials, adjusting the moisture content of materials, adding trace elements to meet the needs of granulation.

|

|

④ Organic fertilizer granulator

|

The cutter head is movable and adjustable, which is conducive to granulation, and is made of wear-resistant alloy. Mainly used for granulation of various powdery materials.

|

|

⑤ Throw round shaping machine

|

The machine is mainly used in conjunction with the granulator to increase the granulation output and achieve smooth and bright appearance of the granules.

|

|

⑥ Rotary dryer

|

It is mainly used for drying after granulation, so that the granules can quickly reduce the moisture at high temperature, which is convenient for storage and achieves continuous and uninterrupted production.

|

|

⑦ Cooling machine

|

It is mainly used to cool down and remove moisture after drying, so that the material can quickly reach normal temperature, meet the storage requirements, and realize continuous and uninterrupted production.

|

|

⑧ Screener machine

|

Wear-resistant steel mesh. It is mainly used for the separation of finished products and returned materials, and can also realize the classification of finished products, so that the finished products can be evenly classified.

|

|

⑨ Coating machine

|

It is mainly used for dusting powder or liquid coating of granules, which can prevent caking and improve brightness. It is also used in various multi-functional bacterial fertilizers.

|

|

⑩ Package machine

|

It is mainly composed of main machine, machine column, sewing machine head and conveyor belt. Different specifications can be packaged to improve work efficiency and reduce operating costs.

|

Applications:

It is widely used in the harmless treatment of organic waste such as livestock and poultry manure, sugar factory filter mud, papermaking sludge, plant straw, urban sewage sludge, urban domestic garbage, peat, soybean meal, potato residue, biogas residue, cigarette residue, etc. to produce organic fertilizer.

Support and Services:

We provide a comprehensive suite of services to assist with any technical challenges you may encounter during the operation of your machine. Our services include:

Technical Assistance: Free CAD design. Our team of skilled technicians is available to provide guidance and answer any questions related to the features, setup, and use of the machine. They can help troubleshoot issues and offer solutions to get your equipment up and running smoothly.

Operational Training: To help you get the most out of your investment, we offer operational training sessions. These sessions are designed to familiarize your staff with the granulator's functions, maintenance procedures, and safety protocols.

Parts and Repair Services: In the event that your machine requires repair or replacement parts, we provide timely assistance. We supply authentic, high-quality parts to ensure your machine operates at its best. Our repair services are carried out by certified professionals who specialize in our Fertilizer crusher systems.

We are committed to delivering exceptional technical support and services to ensure that your Fertilizer dryer operates at peak performance. Our goal is to help you achieve optimal results and maximize the productivity of your agricultural operations.

Packing and Shipping:

Wooden package or full 20GP/40HQ container;

The fertilizer equipment is packaged in sturdy wooden crates to provide maximum protection during transportation. Each crate is designed to fit the specific dimensions of the machine and is lined with shock-absorbing materials to prevent any damages during handling and shipping.

The crates are also sealed tightly to prevent any dust or moisture from entering and potentially affecting the quality of the product. We take extra care to package the granulator in a way that it can withstand rough handling and long-distance transportation.

We ship our machine through reliable and trusted shipping companies to ensure timely and safe delivery. Our team works closely with these companies to track and monitor the shipment to make sure it reaches its destination without any delays or damages.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!