Organic compound fertilizer rotary drum granulator chemical metallurgy granulation

Product Description:

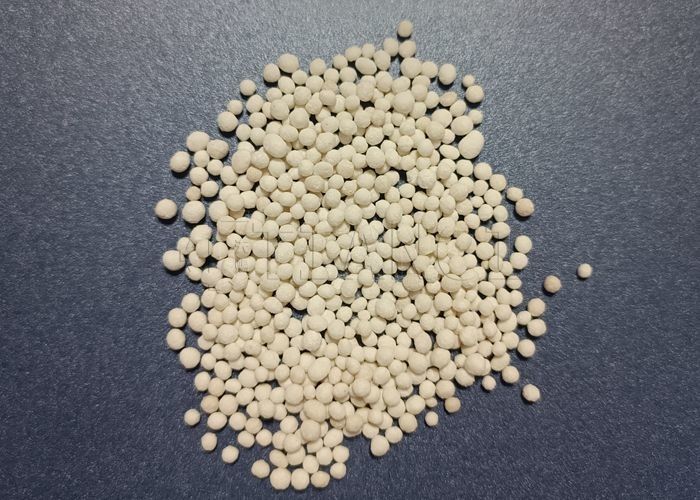

The rotary drum granulator is a molding machine that can make materials into spherical particles. It is one of the key equipment in the compound fertilizer and organic fertilizer industry.

It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. The mechanical cylinder adopts a special rubber plate lining or acid-resistant stainless steel lining, which realizes automatic scar removal and tumor removal, and eliminates the traditional scraper device.

Its working method is wet granulation. Through a certain amount of water or steam, the raw materials are humidified in the cylinder to undergo a full chemical reaction. Under certain liquid phase conditions, with the help of the rotating motion of the cylinder, the material particles are squeezed and agglomerated into balls.

Features:

- High balling rate, small amount of returned materials, small returned material size, and can be re-granulated.

- Steam heating is introduced to increase the material temperature, so that the moisture content of the material after balling is low, and the drying efficiency is improved.

- Rubber engineering plastics are used as linings, so the raw materials are not easy to stick to the barrel and play an anti-corrosion and heat preservation role.

- Large output, low power consumption, and low maintenance costs.

- The production raw materials are widely adaptable: low-solubility (normal calcium, calcium chloride, ammonium sulfate, potassium sulfate, potassium chloride, etc.) and high-solubility (urea, ammonium nitrate, ammonium phosphate, etc.) raw materials can be used in any combination as required, and can also be matched with some organic matter and medium and trace elements.

Technical Parameters:

| Model |

Dip angle

(°)

|

Internal diameter

(m)

|

Length

(m)

|

Speed

(r/min)

|

Power

(kw)

|

Capacity

(t/h)

|

Outline dimension

(L*W*H)

|

| ZG1.2*4 |

2-2.5 |

1.2 |

4 |

17 |

5.5 |

1-3 |

4.6*2.2*2.0 |

| ZG1.4*5 |

2-2.5 |

1.4 |

5 |

14 |

7.5 |

3-5 |

4.8*2.8*2.3 |

| ZG1.5*6 |

2-2.5 |

1.6 |

6 |

11.5 |

11 |

5-8 |

7.0*3.2*3.1 |

| ZG1.8*7 |

2-2.5 |

1.8 |

7 |

11.5 |

15 |

8-10 |

8.5*3.5*3.3 |

| ZG2.0*8 |

2-2.5 |

2.0 |

8 |

11 |

18.5 |

10-15 |

9.1*3.6*3.5 |

| ZG2.2*8 |

2-2.5 |

2.2 |

8 |

10.5 |

22 |

15-20 |

9.5*4.4*3.9 |

Applications:

Suitable for processing powdery materials into ball type granules, widely used in compound fertilizer plants, organic fertilizer plants, sludge waste treatment plants and mines, chemical industry, cat little, animal feed and other industries.

Package and Delivery:

For small single machines, we usually wrap them with protective film and then put them in a sturdy wooden box;

For large equipment or multiple production line equipment, we will place them in containers and secure them with steel wires.

So there's no need to worry about transportation issues.

FAQ

Q: What are your company's advantage ?

A: We are professional fertilizer equipment manufacturer with more than 20 years production experience and 10 years exports experience. We have own factory which can produce high quality equipment with competitive prices.

Q: What information do we need to provide to complete an order ?

A: You should provide us with your fertilizer raw materials and capacity, as well as your production area. Once the quotation content is confirmed, provide us with your destination port.

Q: Do you have customer reviews or case studies available ?

A: Yes, we have many successful overseas cases and customers feedback, such as Uzbekistan, Malaysia, Vietnam, India, Philippines and so on. If you need, you can add my whatsapp number and I will send them to you.

Q: What is your main products ?

A: Our main products include complete equipments of fertilizer production line. There are many types of granulator and some auxiliary equipment (drying&cooling machine, screening machine, coating machine, packaging machine and so on).

Q: How to choose the right fertilizer equipment ?

A: Inder to choose the appropriate equipment, we need to know your fertilizer raw materials and production capacity, so that we can give you a right solution. It’s best for us if you can provide the production area.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!