Product Description:

Rotary drum granulator is widely used in fertilizer production line, it is characterized by high-speed rotating drum to achieve wet grain, so that humidity, shape, size and other factors can be adjusted at any time. In order to ensure the normal operation of the machine and the safety of the operator, we need to fully understand the use methods and operating procedures of the equipment, and do a good job of daily maintenance and inspection of the machine to ensure its long-term stable operation.

Features:

1, the ball formation rate of 70%, a small amount of return material, return material size is small, can be re-granulated;

2, through the steam heating, improve the temperature of the material, so that the material into a ball after low water, improve drying efficiency;

3, with rubber engineering plastics as the lining, raw materials are not easy to stick to the cylinder, and play a role in anti-corrosion insulation;

4, large output, power consumption, low maintenance costs.

Technical Parameters:

Equipments for rotary drum granulator fertilizer production line:

| Automatic batching system |

The automatic batching system includes silos and outriggers, safety nets, weighing belts, and automatic control cabinets. The main function is to reduce work intensity, increase output, achieve continuous production, and improve formula accuracy. |

| Crushing machine |

Mainly used for the crushing of raw materials to meet the requirements of granulation |

| Mixing machine |

It is used for mixing and stirring materials, adjusting the moisture content of materials, adding trace elements to meet the needs of granulation. |

| Rotary drum granulator |

for making the fertilizer granules. |

| Rotary dryer |

It is mainly used for drying after granulation, so that the granules can quickly reduce the moisture at high temperature, which is convenient for storage and achieves continuous and uninterrupted production. |

| Cooling machine |

It is mainly used to cool down and remove moisture after drying, so that the material can quickly reach normal temperature, meet the storage requirements, and realize continuous and uninterrupted production. |

| Screener machine |

Wear-resistant steel mesh. It is mainly used for the separation of finished products and returned materials, and can also realize the classification of finished products, so that the finished products can be evenly classified. |

| Coating machine |

It is mainly used for dusting powder or liquid coating of granules, which can prevent caking and improve brightness. It is also used in various multi-functional bacterial fertilizers. |

| Package machine |

It is mainly composed of main machine, machine column, sewing machine head and conveyor belt. Different specifications can be packaged to improve work efficiency and reduce operating costs. |

Applications:

Rotary drum granulator is a fertilizer machine that can make raw materials into spheres. Drum granulator is one of the key equipment in compound fertilizer industry, which is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizer.

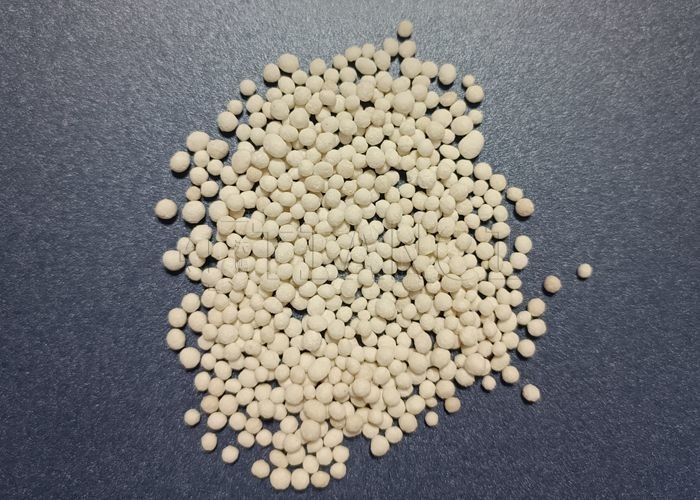

Finished Granules:

Our rotary drum granulators can produce pellets of different sizes and shapes according to your needs.

Packing and Shipping:

Our organic fertilizer poroduction line machine are now safely packed in sturdy shipping cabinets to ensure it reaches your destination in perfect condition.

For transportation, we work with trusted logistics experts who specialize in the safe handling and delivery of heavy equipment. The product is securely bundled to guarantee stability and minimize the risk of moving or tipping during transportation. We offer a variety of transportation options based on your emergency and budget requirements. Rest assured that our team is committed to providing you with comprehensive tracking information so that you can monitor the progress of your shipment until it reaches its destination.

FAQ:

Q: What is the application of the Rotary Drum Granulator Organic Fertilizer Production Line?

A: The application of this production line is to convert organic raw materials into fertilizer granules.

Q: What are the raw materials used in this production line?

A: The raw materials include compost manure, farm waste, city garbage, and other organic materials.

Q: What is the production process involved in this production line?

A: The production process includes crushing, mixing, granulating, screening, and packaging.

Q: What is the capacity range of this production line?

A: The capacity of the production line ranges from 1 to 20 tons per hour.

Q: What is the acceptable humidity level of the raw materials for this production line?

A: The raw material humidity should be equal to or less than 30%.

Q: What is the shape of the granules produced by this production line?

A: The granules produced are of the ball type.

Q: Is the production line fully automated?

A: Yes, the production line is fully automatic, enhancing efficiency and reducing labor requirements.

Q: What is the model number of this fertilizer production line?

A: The model number of this fertilizer production line is ZGX.

Q: Where is this fertilizer production line made?

A: This fertilizer production line is made in China.

Q: Does this fertilizer production line come with any certifications?

A: Yes, this fertilizer production line comes with ISO9001 certification.

Q: What is the minimum order quantity for this fertilizer production line?

A: The minimum order quantity for this fertilizer production line is 1 set.

Q: How is this fertilizer production line packaged for delivery?

A: This fertilizer production line is packaged in a wooden package for delivery.

Q: What are the payment terms for this fertilizer production line?

A: The payment terms for this fertilizer production line are L/C and D/P.

Q: What is the delivery time for this fertilizer production line?

A: The delivery time for this fertilizer production line is 5-8 work days.

Q: What is the supply ability for this fertilizer production line?

A: The supply ability for this fertilizer production line is 30 sets per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!