Goat manure is a high-quality raw material for making organic fertilizer. It is rich in nitrogen, phosphorus, potassium and other nutrients and organic matter. After processing, it can become efficient and environmentally friendly organic fertilizer. The following is a detailed introduction to the Goat manure processing organic fertilizer production line, including process, equipment and related points:

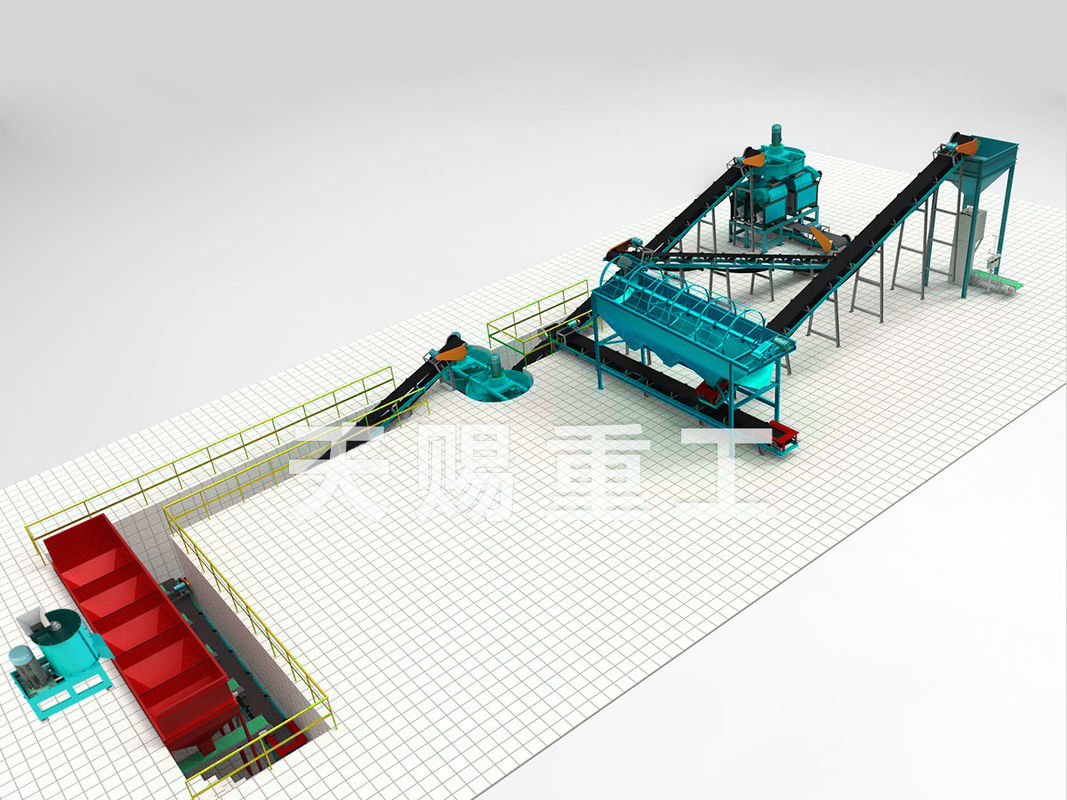

(Figure: Production line process flow chart)

1. Process flow diagram of processing organic fertilizer from Goat manure

|

Goat manure collection → pretreatment (drying/dehydration) → ingredient mixing → fermentation and composting → crushing and screening → granulation → drying and cooling → screening and packaging → finished product

|

2. Core process steps and technical points

1. Raw material collection and pretreatment

• Raw material requirements : Collect fresh Goat manure, and control the moisture content to 60%~65% (it can be squeezed into a ball without falling apart, and water can be seen between fingers without dripping). If the moisture content is too high (such as moisture content > 70%), it is necessary to adjust the moisture content by drying in the sun, mechanical dehydration (dehydrator) or adding crude fiber materials such as straw and rice husk.If the moisture content is lower than this, dehydration is not required.

• Purpose of pretreatment : Reduce moisture content to avoid poor aeration and incomplete composting due to excessive humidity during fermentation, and reduce the load on subsequent equipment.

(Figure: Manure dewatering machine)

2. Ingredients and Mixing

• Ingredients :

◦ Goat manure is the main ingredient (accounting for 60%~70%), and conditioners such as straw and sawdust are added (20%~30%, adjusting the carbon-nitrogen ratio to 25:1~30:1).

◦ Maturation bacteria (such as EM bacteria, yeast, etc., added at 0.1%~0.2% of the raw material amount) can be added to accelerate the fermentation process.

◦ If you need to improve the fertilizer efficiency, you can add appropriate amounts of nitrogen, phosphorus and potassium fertilizers (such as superphosphate, potassium sulfate) or trace elements (boron, zinc, etc.).

• Mixing equipment : horizontal mixer, double-shaft mixer, to ensure uniform mixing of materials and lay the foundation for fermentation.

3. Fermentation and ripening (key link)

• Fermentation method :

◦ Strand fermentation : pile the mixed materials into strips 1.5~2 meters high and 2~3 meters wide, and use a straw turner to turn them regularly (once a day in the early stage and once every 2~3 days in the later stage) to ensure oxygen supply and promote the reproduction of aerobic microorganisms.

◦ Tank fermentation : carried out in a fermentation tank, turned by a tank turner or a crawler turner, with a high degree of automation, suitable for large-scale production, and a fermentation cycle of about 15 to 25 days.

• Fermentation control parameters :

◦ Temperature: At the beginning of fermentation, the temperature rises to 50~60℃ and is maintained for 3~5 days to kill pathogens, insect eggs and weed seeds; after the high temperature period, the temperature gradually drops to below 40℃, indicating that the composting is complete.

◦ Humidity: Maintain 50%~60%. Spray water when it is too dry. Turn and ventilate when it is too wet.

◦ Fermentation cycle: Conventional strip fermentation takes about 30 to 45 days, while tank fermentation can be shortened to 15 to 20 days.

• Maturity judgment criteria : The material is dark brown in color, odorless, with a faint musty smell, loose in texture, easily broken by hand, with an organic matter content of ≥45% and a moisture content of ≤30%.

(Left: Wheel-type compost turner; Right: Crawler-type compost turner)

4. Crushing and screening

• Crushing equipment : semi-wet material crusher, hammer mill, crush the decomposed Goat dung blocks to a particle size of ≤5mm for subsequent granulation.

• Screening equipment : Vibrating screen (10~20 mesh), screen out unqualified coarse particles, return them to the crusher for re-crushing to ensure uniform particle size of the material.

5. Granulation (select according to demand)

• Granulation method and equipment :

◦ Disc granulator : simple structure, small investment, suitable for small and medium-sized production, spherical particles, particle size 2~5mm, granulation rate 70%~80%.

◦ Extrusion granulator : through mechanical extrusion molding, the granules have high hardness, suitable for making organic fertilizer with uniform granules, with a granulation rate of more than 85% and low energy consumption.

◦ Drum granulator : suitable for large-scale production, high output (5~10 tons/hour), good particle strength, but the equipment investment is relatively large.

• Granulation conditions : The moisture content of the material is controlled at 20%~25%, the temperature is 30~40℃, and a small amount of binder (such as bentonite, the addition amount is ≤5%) can be added before granulation to improve the granulation rate.

(Left: Double roller press extrusion granulator; Right: Flat-die extrusion granulator)

6. Drying and cooling

• Drying equipment : Rotary dryer, using hot air (temperature 80~120℃) to reduce the moisture content of the particles to below 10%. The drying time is about 30~60 minutes, and the output depends on the equipment specifications (such as Φ1.2×12m dryer, the output is about 1~2 tons/hour).

• Cooling equipment : counter-current cooler or air-cooled cooler to reduce the pellet temperature to ≤ ambient temperature + 5℃ to avoid moisture and agglomeration during storage.

7. Screening and packaging

• Screening : The particles are screened out through the vibrating screen again to obtain qualified particles (2-5 mm). The unqualified particles are returned to the granulator for reprocessing.

• Packaging : Automatic weighing and packaging machine, packing into 25kg, 50kg bags, or ton bags according to needs, labeling and storage.

3. List of main equipment and their functions

|

Device Type

|

Specific equipment

|

Functional Description

|

Applicable scale

|

|

Pretreatment equipment

|

Dehydrator, Turner

|

Reduce the moisture content of Goat manure and turn the material to adjust humidity and ventilation

|

Medium and large production lines

|

|

Mixing equipment

|

Horizontal mixer, twin-shaft mixer

|

Evenly mix Goat manure, conditioners, bacterial agents and other raw materials

|

Production lines of various sizes

|

|

Fermentation equipment

|

Windrow type turner, trough type turner

|

Turning materials promotes aerobic fermentation and controls temperature and oxygen content

|

The stack type is suitable for small and medium-sized, and the trough type is suitable for large

|

|

Crushing and screening equipment

|

Semi-wet material crusher, vibrating screen

|

Crush the decomposed materials and remove impurities and coarse particles

|

Production lines of various sizes

|

|

Granulation equipment

|

Disc granulator, extrusion granulator

|

Make crushed materials into granular organic fertilizer to improve marketability and ease of application

|

Disc/extrusion for small and medium, drum for large

|

|

Drying and cooling equipment

|

Rotary dryers, coolers

|

Reduce the moisture content of the particles, prevent moisture during storage, and facilitate transportation and storage

|

Production lines of various sizes

|

|

Packaging Equipment

|

Automatic weighing packaging machine

|

Quantitative packaging to improve production efficiency and product standardization

|

Production lines of various sizes

|

IV. Production Line Investment and Scale Recommendations

1. Small production line (1~2 tons/hour)

• Equipment investment : about 150,000 to 300,000 yuan (excluding factory buildings and land).

• Equipment configuration : simple turning machine, horizontal mixer, semi-wet material crusher, disc granulator, small dryer, manual packaging equipment.

• Suitable scenarios : Farms or small organic fertilizer plants, with an annual production capacity of 5,000 to 10,000 tons.

2. Medium-sized production line (5~8 tons/hour)

• Equipment investment : approximately 500,000 to 1,000,000 yuan.

• Equipment configuration : trough type turning machine, double-shaft mixer, extrusion granulator, rotary dryer, cooler, automatic screening and packaging line.

• Suitable scenarios : Professional organic fertilizer production companies with an annual production capacity of 30,000 to 50,000 tons, which can be sold externally.

3. Large production line (more than 10 tons/hour)

• Equipment investment : more than 1 million yuan (automatic production line can be customized).

• Equipment configuration : fully automatic fermentation tank system, intelligent batching and mixing equipment, rotary drum granulator, large drying and cooling system, intelligent packaging line.

• Suitable scenarios : Large-scale organic fertilizer enterprises with an annual production capacity of more than 50,000 tons, which can be connected to agricultural cooperatives and planting bases.

5.Production scene of Tianci Heavy Industry

6.Delivery

7.FAQ

Q: What are the typical raw materials used in this production line?

A: The raw materials used in the Organic Fertilizer Granules Production Line include compost manure, farm waste, city garbage, and other organic materials.

Q: What is the capacity range of this production line?

A: The capacity of the Organic Fertilizer Granules Production Line ranges from 1 to 300 tons per hour.

Q: What is the maximum allowable humidity level for raw materials in this production line?

A: The maximum allowable humidity level for raw materials in the Organic Fertilizer Granules Production Line is ≤30%.

Q: Is this production line automated?

A: Yes, the Organic Fertilizer Granules Production Line is fully automatic, minimizing manual intervention and maximizing efficiency.

Q: What are the key steps involved in the production process?

A: The production process of the Organic Fertilizer Granules Production Line includes crushing, mixing, granulating, screening, and packaging.

Q: What is the shape of the granules produced by this production line?

A: The granules produced by the Organic Fertilizer Granules Production Line have a ball-type shape.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!